Chocolate is more than just a delightful treat. It’s an art form, a business, and, for many, a lifelong passion. At the heart of many chocolate operations lies a tool that quietly works its magic—the chocolate transfer pump. While they may not get the same attention as a chocolatier’s skilled hands, these pumps play a vital role in shaping the chocolate industry. This blog post will explore the unique applications of chocolate transfer pumps, highlighting how they bridge the gap between artistic designs and industrial manufacturing.

Understanding Chocolate Transfer Pumps

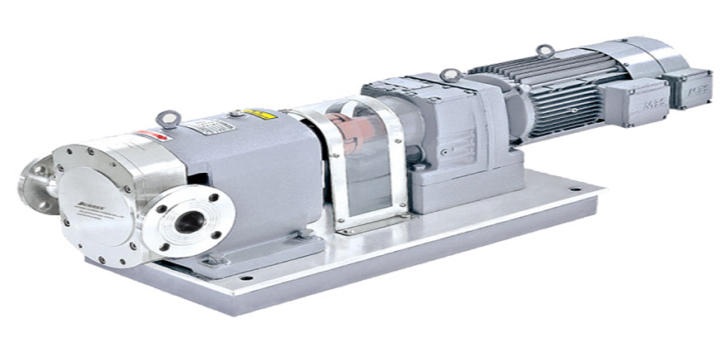

Before we jump into their applications, let’s first understand what a chocolate transfer pump is. Essentially, these pumps are specialized devices designed to move liquid chocolate efficiently from one place to another. They maintain consistent flow and temperature, ensuring that the chocolate remains smooth and glossy. These pumps are invaluable in chocolate production, providing the precision needed at various stages of the process.

Chocolate transfer pumps have a simple yet effective design that facilitates their function. Equipped with stainless steel components, they meet the strict hygiene standards necessary for food production. Additionally, many pumps come with adjustable settings, enabling chocolatiers to control the flow and temperature of the chocolate precisely. This adaptability makes them a favorite in both small artisanal shops and large manufacturing facilities.

One of the key challenges in working with chocolate is maintaining its consistency. Chocolate transfer pumps effectively tackle this issue by ensuring a uniform flow, preventing blockages and maintaining the desired texture. This consistency is crucial for the quality of the final product, whether it’s a simple bar or an intricate design.

Artistic Applications in Chocolatiers

Chocolate is an art, and for chocolatiers, every creation is a masterpiece. Chocolate transfer pumps play a significant role in the artistic process, allowing for intricate designs and finishes. From creating delicate patterns to achieving the perfect sheen, these pumps provide the precision chocolatiers need.

In artisanal chocolate shops, creativity is paramount, and chocolate pumps help bring that vision to life. Chocolatiers often use these pumps to fill molds with precision, ensuring that each piece is uniform and visually appealing. Additionally, they enable the creation of multi-layered confections, adding depth and complexity to the flavor profile.

Beyond aesthetics, chocolate pumps also contribute to flavor consistency. By maintaining a steady flow of chocolate, they help ensure that each piece tastes as intended. This consistency is critical for chocolatiers striving to build a loyal customer base. After all, a consistently delicious product keeps customers coming back for more.

Streamlining Industrial Manufacturing

While artisanal chocolatiers focus on small-batch production, the industrial sector takes chocolate manufacturing to a larger scale. In these settings, chocolate transfer pumps are indispensable, streamlining the production process and ensuring efficiency.

In large-scale chocolate factories, these pumps handle vast quantities of chocolate daily. They move the chocolate seamlessly between different stages of production, from melting and tempering to molding and packaging. This automation reduces the need for manual intervention, saving time and labor costs.

Furthermore, chocolate pumps contribute to sustainability in industrial manufacturing. By optimizing the production process, they help minimize waste and energy consumption. This efficiency aligns with the growing emphasis on sustainable practices in the food industry, benefiting both the environment and the company’s bottom line.

Meeting Specific Industry Needs

The versatility of chocolate transfer pumps extends beyond traditional chocolate production. They are also employed in various niche applications, catering to specific industry needs. For example, in the pharmaceutical sector, chocolate pumps are used to coat pills and tablets. This coating masks unpleasant flavors and facilitates easier swallowing.

In the cosmetics industry, chocolate pumps find their use in creating chocolate-infused beauty products. These products capitalize on chocolate’s natural antioxidants and moisturizing properties, appealing to consumers seeking natural and indulgent skincare solutions.

The ability of chocolate pumps to adapt to different industries underscores their importance. They offer solutions that go beyond traditional chocolate applications, showcasing their versatility and the innovative possibilities they bring to the table.

Precision and Consistency in Every Batch

One of the most significant advantages of chocolate transfer pumps is their ability to deliver precision and consistency in every batch. Whether in artisanal or industrial settings, this consistency is crucial for maintaining product quality and meeting customer expectations.

In artisanal chocolate shops, precision is essential for creating intricate designs and maintaining flavor profiles. With the help of chocolate pumps, chocolatiers can achieve the exact thickness and texture required for each creation. This attention to detail elevates the final product, leaving a lasting impression on consumers.

In industrial manufacturing, consistency is key to meeting production quotas and quality standards. Chocolate pumps ensure that each batch is identical in taste and appearance, allowing manufacturers to produce large quantities without compromising quality. This reliability is vital for building a brand’s reputation and gaining consumer trust.

Overcoming Challenges in Chocolate Production

Chocolate production comes with its own set of challenges, and chocolate transfer pumps are a valuable tool in overcoming them. One common challenge is maintaining the right temperature throughout the process. Chocolate is sensitive to temperature fluctuations, and even a slight change can affect its texture and appearance.

Chocolate pumps address this issue by incorporating temperature control mechanisms. These mechanisms keep the chocolate at the ideal temperature, preventing undesirable changes in consistency. This precision ensures that the final product is smooth, glossy, and visually appealing.

Another challenge is preventing chocolate from solidifying during production. Chocolate transfer pumps are designed to handle this by maintaining a continuous flow, preventing chocolate from cooling and hardening prematurely. This feature is particularly useful in industrial settings where interruptions in production can lead to costly delays.

Enhancing Safety and Hygiene Standards

In food production, safety and hygiene are paramount. Chocolate transfer pumps are designed with these considerations in mind, ensuring that they meet the rigorous standards required in the industry. Stainless steel components and seamless construction make them easy to clean and maintain, reducing the risk of contamination.

Furthermore, chocolate pumps are equipped with features that enhance safety during operation. Automatic shut-off mechanisms and temperature sensors prevent overheating and potential accidents. This focus on safety ensures a smooth production process and provides peace of mind for operators and manufacturers.

The emphasis on hygiene and safety extends to the consumer as well. By maintaining strict standards, chocolate pumps contribute to the overall quality and safety of the final product, ensuring that it reaches consumers in its best form.

Future Innovations in Chocolate Technology

The world of chocolate technology is continually evolving, and chocolate transfer pumps are no exception. Manufacturers are exploring new ways to enhance these pumps’ capabilities, incorporating advanced features that boost efficiency and performance.

One area of innovation is the integration of smart technology. Smart chocolate pumps can be connected to digital platforms, allowing operators to monitor and control the production process remotely. This connectivity streamlines operations, allowing for real-time adjustments and reducing the need for manual intervention.

Additionally, manufacturers are developing eco-friendly chocolate pumps that prioritize sustainability. These pumps are designed to minimize energy consumption and waste, aligning with the industry’s commitment to reducing its environmental footprint. Such innovations are not only beneficial for the planet but also contribute to the long-term success of chocolate producers.

In conclusion, chocolate transfer pumps are unsung heroes in the chocolate industry, quietly contributing to both artistry and efficiency. From the careful crafting of intricate designs to the streamlined production in large factories, these pumps play a crucial role in shaping the chocolate we love.

The versatility of chocolate pumps extends beyond traditional chocolate production, finding applications in various industries such as pharmaceuticals and cosmetics. Their ability to deliver precision, consistency, and safety makes them indispensable tools for chocolatiers and manufacturers alike.

As the industry continues to evolve, chocolate transfer pumps will remain at the forefront of innovation, driving advancements in chocolate technology. Whether you’re a small artisanal chocolatier or a large industrial manufacturer, these pumps are the key to unlocking the full potential of chocolate production.